About us

Funmak was founded in 1992 as a Zamak pressure injection moulding company focused on Lean Manufacturing and Continuous Improvement, supplying all industrial sectors with the automotive industry as the main one.

With the experience, know-how, human resources, machinery and suppliers, we are able to produce parts from 10 grams to 5 kg in pieces with high technical requirements according to our customers’ needs.

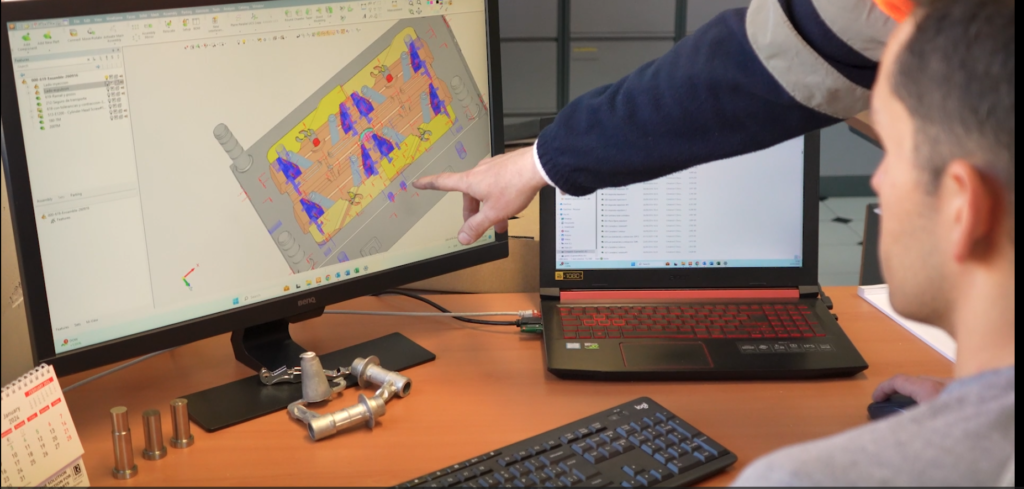

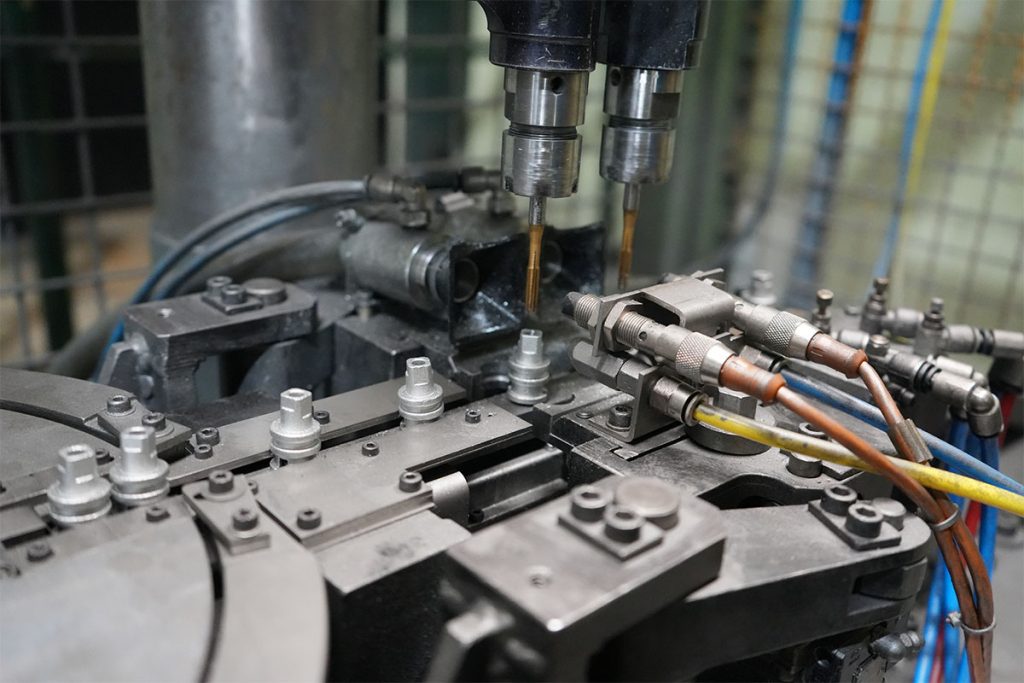

Machinery and equipment

Die-Casting Injection Machines

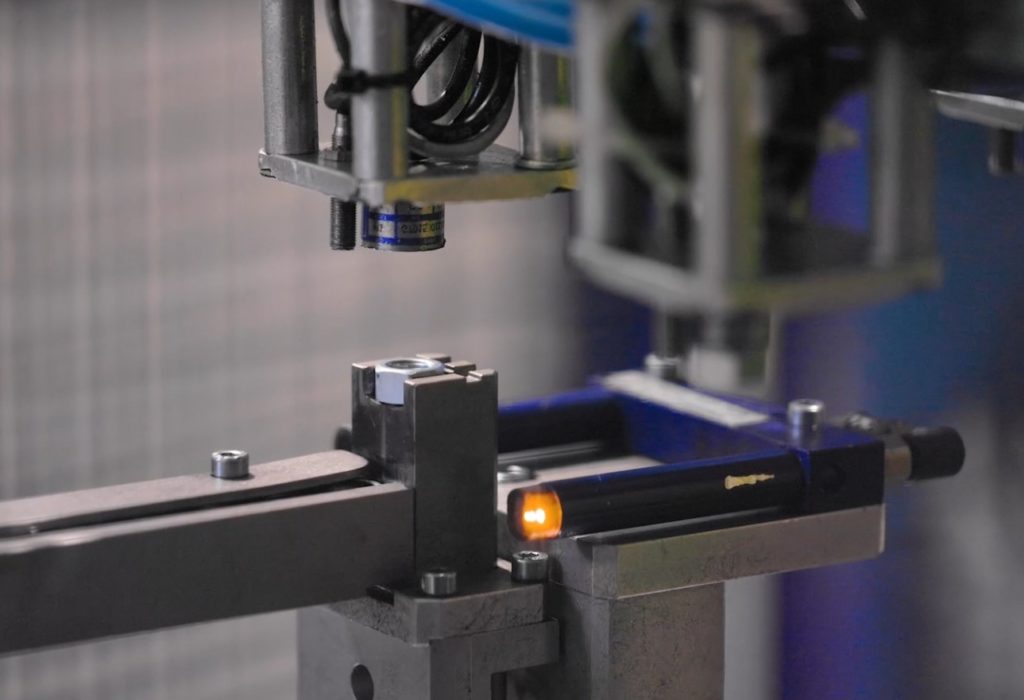

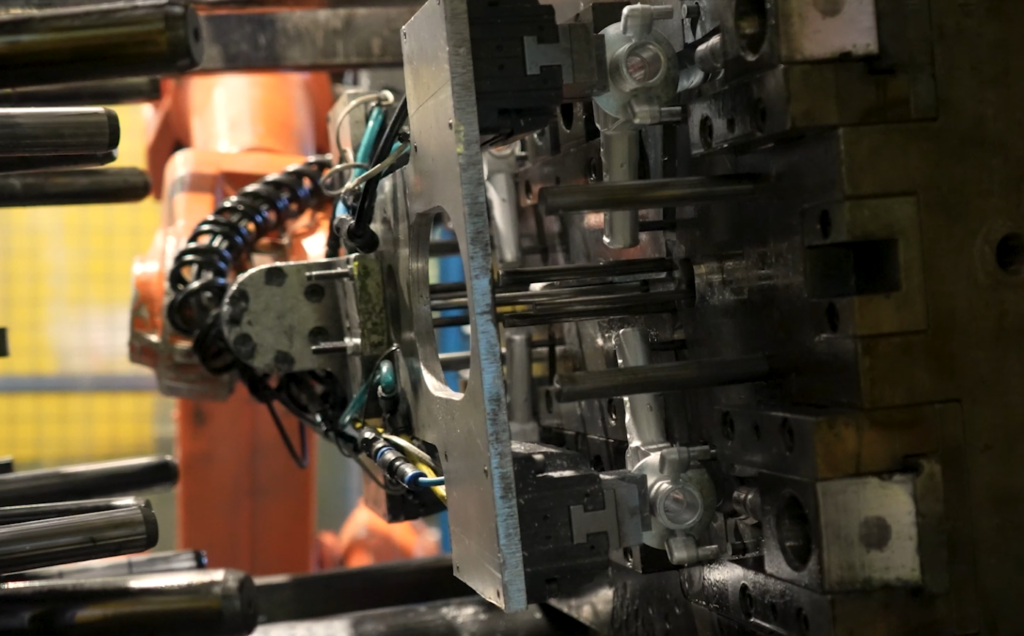

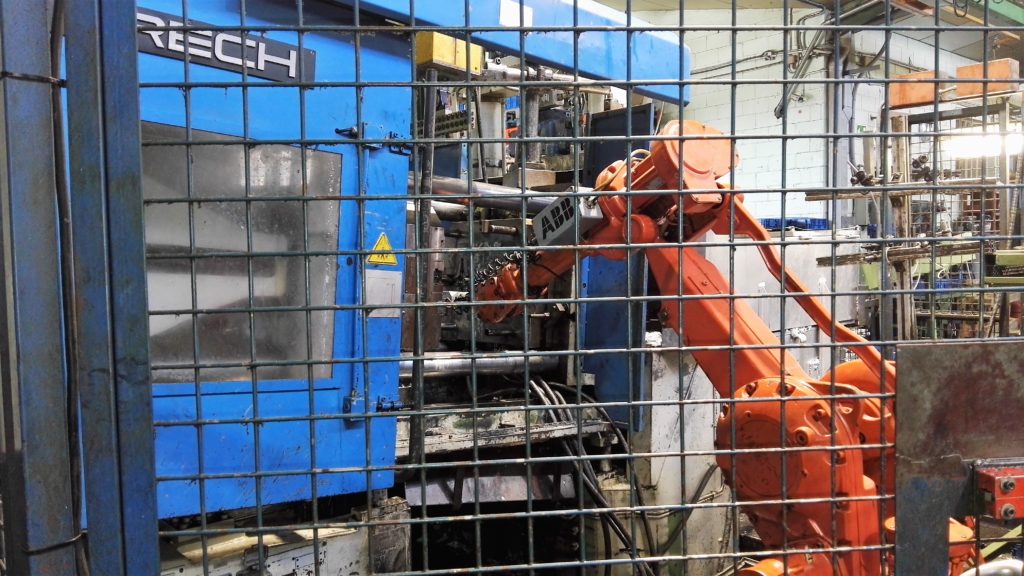

All our machines are from Frech manufacturer and are equipped with peripherals that allow us to fully automate our injection moulding process.

RC machines are capable of injecting sealed and burr-free parts, resulting in savings for the customer with optimum and constant quality due to the real-time control which allows full control of the injection curves.

| Ton | Cantidad | Modelo |

|---|---|---|

| 40 | 1 | Frech |

| 63 | 1 | Frech |

| 80 | 1 | Frech |

| 125 | 2 | Frech |

| 160 | 2 | Frech |

| 200 | 1 | Datacontrol RC |

| 200 | 1 | Frech Datavario |

| 315 | 1 | Frech DCRC |

Peripherals and production methods

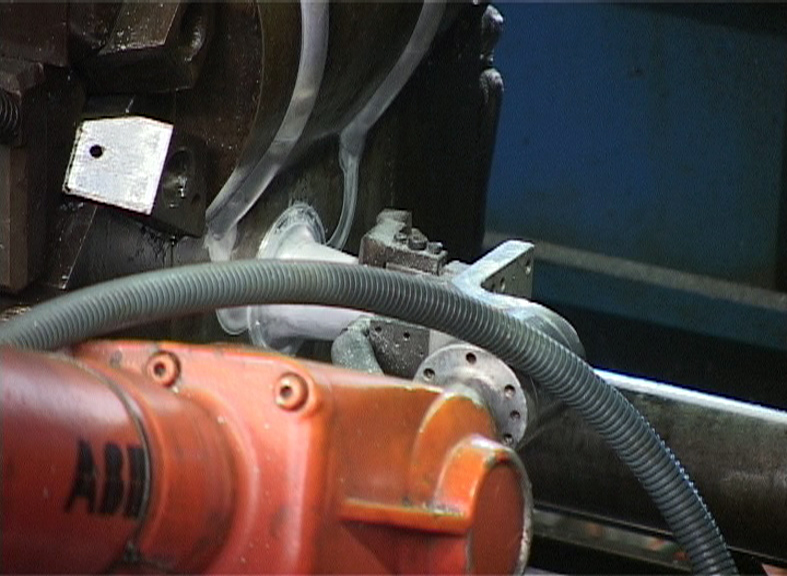

We have injection units with high-tech machines and automated peripheral systems that allow us to obtain parts that are deburred and fitted into the packaging required by our customers in the same injection phase.

Our know-how combined with a Lean Manufacturing system allows us to obtain parts with threads and dimensions of thousandth tolerances in the same injection moulding process, thus avoiding the need, in many cases, for subsequent machining manipulation to obtain these dimensions of thousandth tolerances. Along with this process, Funmak, through its Know How, avoids investment costs in tooling for matrix / deburring (separation of parts versus material feeding spurs) as well as the same cost of this production process.

Funmak has a wide range of complementary processes adapted to the needs of our customers. As a summary it would be assembly process, rubber inserts, bushings, pins, threading, etc. Furthermore, it offers any type of finish with specific roughness and surface treatments such as painted, chrome-plated or zinc-plated parts.

| Cantidad | Modelo |

|---|---|

| 3 | Robots ABB IRB 2400 |

| 1 | Robot KUKA |

| 4 | Prensas Hidráulicas de Desbarbado |

| 3 | Máquinas de Granallado Automáticas |

| 1 | Máquina de Granallado Manual |

| 4 | Cámaras con visión artificial y IA |

| 9 | Sistemas automáticos para separar bolsas y coladas |

| 9 | Lubrificadores Frech |

| 3 | Sistemas de refrigeración |

| 3 | Equipos de Vacío |

| 5 | Alimentadores automáticos de material con visión y detección láser |

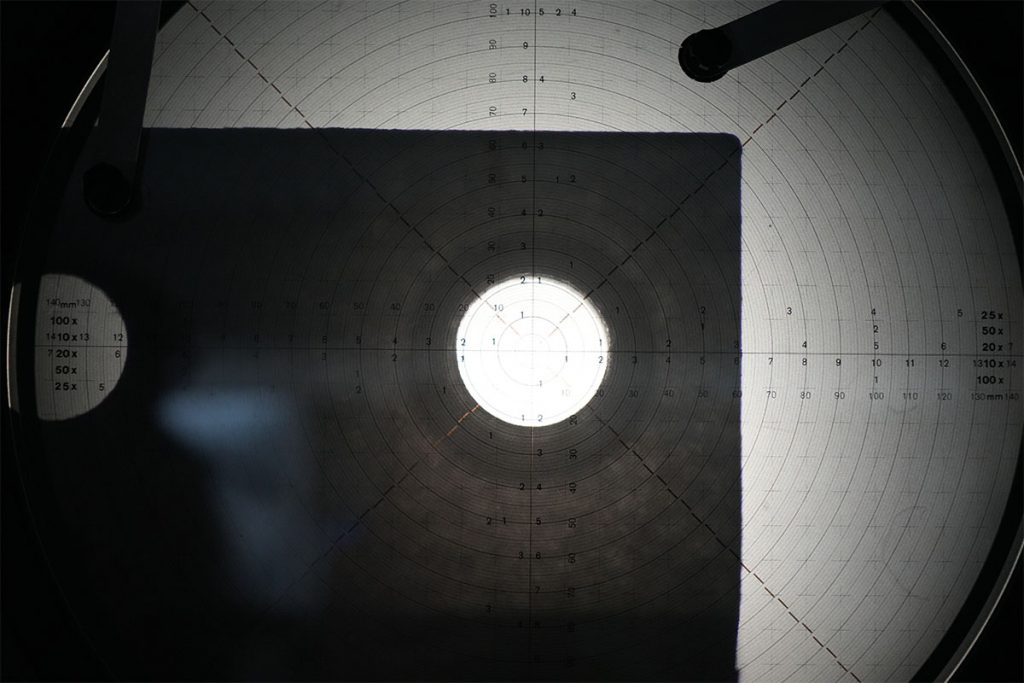

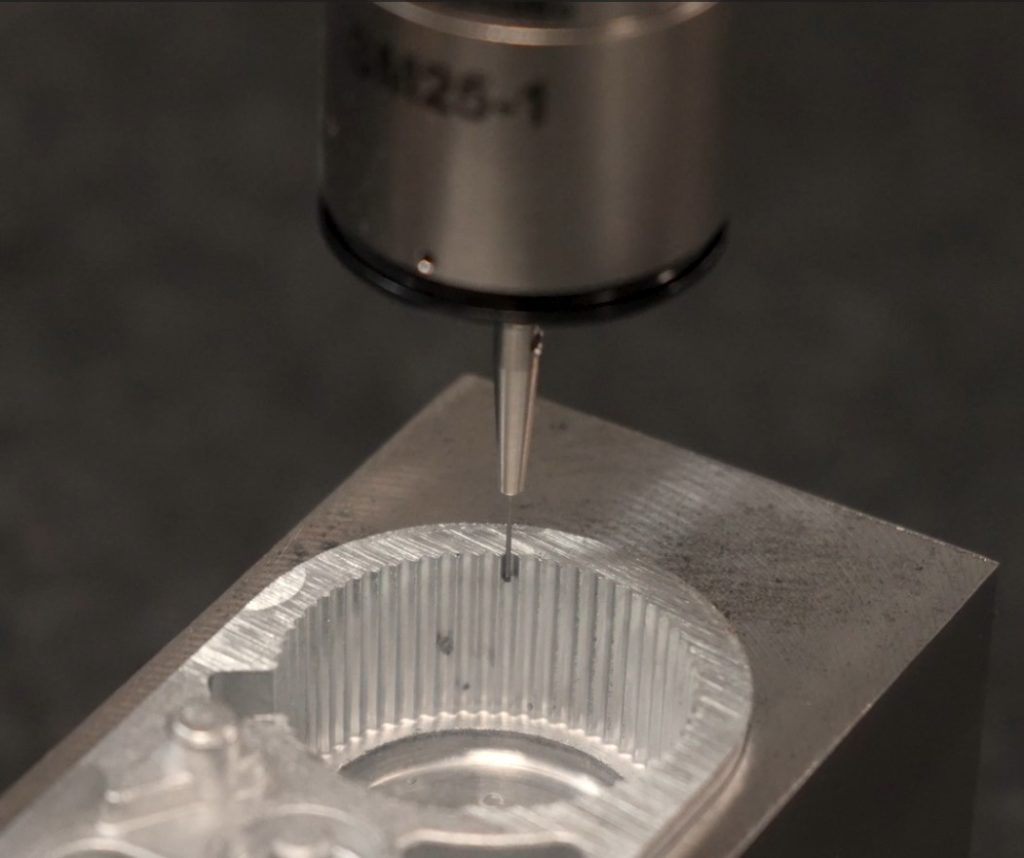

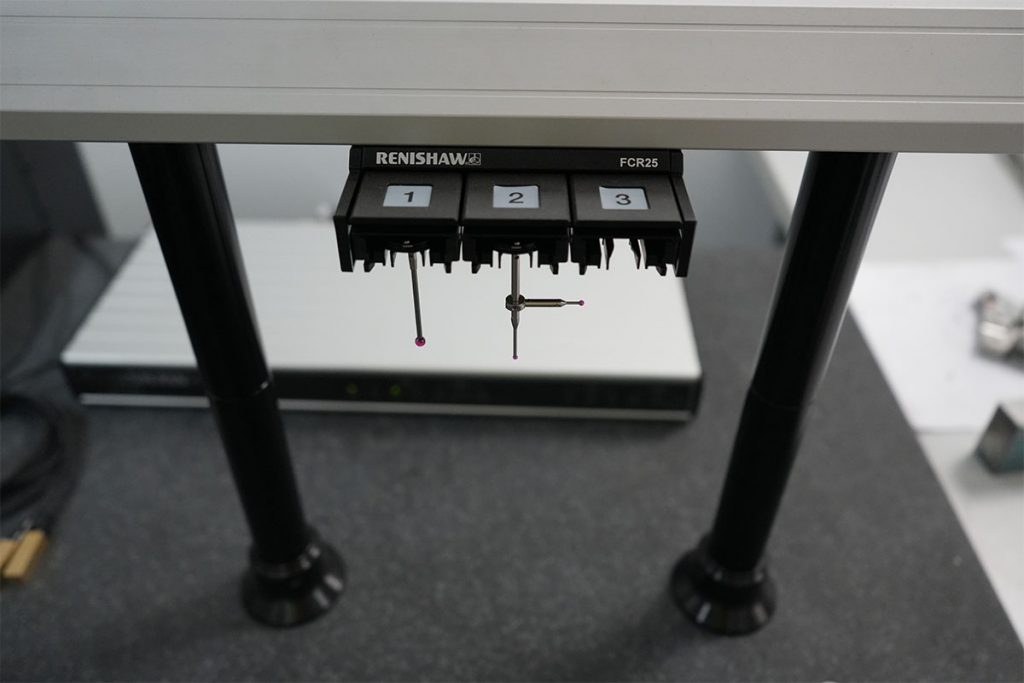

Quality Equipment

The best know-how combined with the best machines for being the most robust and reliable on the market.

| Cantidad | Modelo |

|---|---|

| 1 | Máquina tridimensional 3D Automática (Mitutoyo) |

| 1 | Balanza Electrónica de Precisión |

| 1 | Pulidora de Metales |

| 1 | Máquina de control de compresión y tensión |

| 1 | Horno con temperatura de 0ºC a 250ºC |

| 1 | Cámara de niebla salina |

| 1 | Proyector de perfiles |

| 1 | Estereoscopio de hasta 40 aumentos con cámara fotográfica |

OUR

History

Three generations of industrial history

Mr. Josep Tomàs Piñol, a renowned mould maker, founded SATYR in 1970, a company dedicated to Aluminium and Zamak injection moulding. This was highly technical and remarkable at the time as it achieved at that early stage, no machining of H7 diameters in Zamak parts as well as significant cost improvements based on automation and simplification of processes.

In 1992, Mr. Tomàs and his son Josep Maria, together decided to dedicate themselves entirely to the injection of Zamak parts, thus achieving the re-fusion of the feeding system of the parts, the so-called “sprue”, allowing the parts to already come out with the shot-blasted finish in the same work station. In other words, manufacturing without waste, an exponential saving through the fact of not using dies and at the same time obtaining the shot-blasted parts without using any staff to do the job, as everything was automated from that moment onwards.

As a result of such technical and productive achievements, an important global supplier to the automotive industry challenged our company to achieve Pivot Housings in unmachined aluminium, however, this was achieved and involved The company’s success was a turning point and it is still going strong with enormous benefits for the automotive supply industry.

Nowadays, the third generation has taken over the reins of Funmak following the philosophy of success: in-depth examination of the part to be manufactured, bringing improvements to our customers. Focused on Lean Manufacturing and minimising production processes as much as possible through Continuous Improvement whilst respecting excellence in quality and service level.

1992

2024

OUR

Facilities

Funmak's Quality

Since 2004 we are IATF 16949 certified and we are working on the basis of VDA 6.3 and VDA 6.5 for the automotive sector.

Total Quality is ultimately a culture based on a common language methods and tools described in the Quality Management System, which requires the permanent involvement of all members of the organisation in order to improve the following:

- Strategic decisions and objectives.

- Internal indicators.

- Functioning.

- Products and services, in conjunction with their environment.

Deploying the Quality Policy to each department of the company ensures that it is properly understood and effectively implemented in day-to-day operations, and creates a framework for setting and monitoring Quality Objectives within the Quality Committee and/or Management Reviews.

Documentation

Quality

Approved by Lloyd’s Register in accordance with IATF 16949:2016 standards.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.